Are you tired of using traditional tools like saws, scissors, and chisels to create your DIY projects at home? Do you want to add more precision and detail to your creations? Then it’s time to consider investing in a home laser cutting and engraving machine.

With the advancement of technology, home laser cutting and engraving machines have become more accessible and affordable than ever before. These machines use high-powered lasers to cut and engrave a variety of materials, including wood, plastic, leather, fabric, and even metal. They can help you bring your ideas to life with intricate designs and clean cuts that are difficult to achieve with traditional tools.

In this article, we’ll explore the benefits of home laser cutting and engraving machines, how they work, and what to consider when choosing the right one for your needs.

Benefits of Home Laser Cutting and Engraving Machines

Precision: Laser cutting and engraving machines offer precise cuts and intricate designs that are difficult to achieve with traditional tools. They allow you to create complex shapes and patterns with ease, giving you the freedom to unleash your creativity.

Versatility: Home laser cutting and engraving machines can cut and engrave a variety of materials, including wood, plastic, leather, fabric, and even metal. This makes them ideal for a wide range of DIY projects, from personalized gifts to home decor and even custom jewelry.

Time-Saving: Laser cutting and engraving machines are fast and efficient. They can complete projects in a fraction of the time it takes to do them manually. This saves you time and energy and allows you to focus on other aspects of your project.

Cost-Effective: While the initial investment in a home laser cutting and engraving machine may seem expensive, it can save you money in the long run. By being able to create your own designs and cut your own materials, you can save on outsourcing costs and create more customized products.

How Home Laser Cutting and Engraving Machines Work

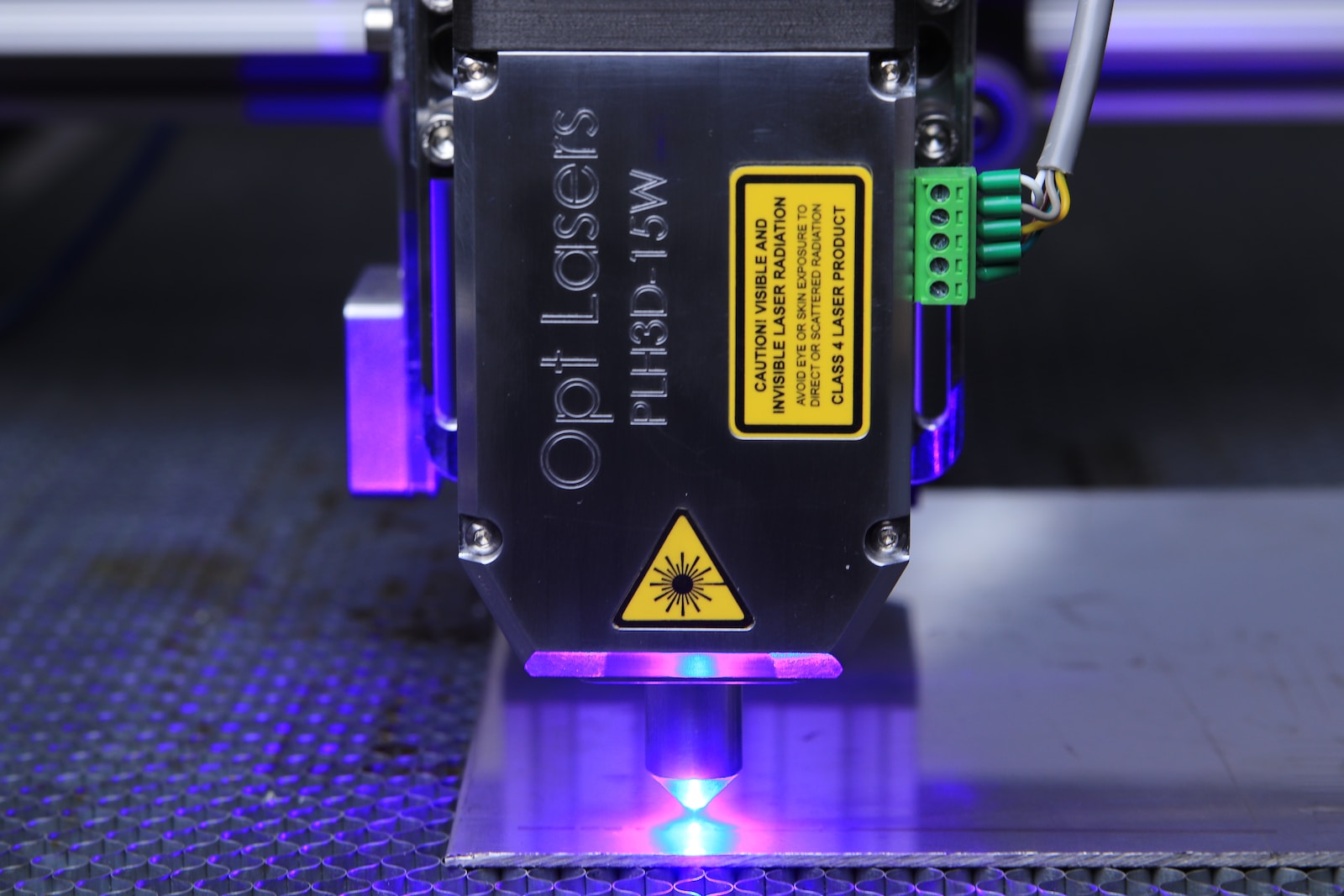

Home laser cutting and engraving machines work by using a high-powered laser to cut and engrave materials. The laser beam is directed onto the material, which is then melted or vaporized, creating a precise cut or engraving. The laser beam is controlled by a computer, which uses software to create the design and control the laser’s movement.

What to Consider When Choosing a Home Laser Cutting and Engraving Machine

Power: The power of the laser determines the materials that can be cut and the speed at which they can be cut. If you plan on cutting thicker or harder materials, you’ll need a machine with more power.

Bed Size: The size of the bed determines the maximum size of the material that can be cut. If you plan on cutting larger materials, you’ll need a machine with a larger bed.

Software: The software used to control the laser and create designs is crucial. Look for a machine with user-friendly software that allows you to import and create designs easily.

Price: Home laser cutting and engraving machines can range in price from a few hundred dollars to several thousand dollars. Determine your budget and look for a machine that meets your needs without breaking the bank.

FAQs

Q: What materials can be cut and engraved with a home laser cutting and engraving machine?

A: Home laser cutting and engraving machines can cut and engrave a variety of materials, including wood, plastic, leather, fabric, and even metal.

Q: Is it difficult to use a home laser cutting and engraving machine?A: While there may be a learning curve when it comes to using a laser cutting and engraving machine, most machines come with user-friendly software and guides to help you get started. With practice and patience, you’ll be able to create amazing designs in no time.

Q: Are home laser cutting and engraving machines safe to use?

A: When used properly and with proper safety precautions, home laser cutting and engraving machines are safe to use. It’s important to follow the manufacturer’s instructions, wear protective gear, and never leave the machine unattended while in use.

Q: Can home laser cutting and engraving machines be used for commercial purposes?

A: While home laser cutting and engraving machines are designed for personal use, they can be used for small-scale commercial purposes. However, if you plan on using the machine for commercial purposes, it’s important to check with local laws and regulations to ensure compliance.

Conclusion

Home laser cutting and engraving machines are a game-changer for DIY enthusiasts and creatives. With their precision, versatility, and time-saving benefits, they allow you to bring your ideas to life with ease. When choosing the right machine for your needs, consider factors such as power, bed size, software, and price. With a little practice and patience, you’ll be able to create stunning designs that will amaze your friends and family. So why not invest in a home laser cutting and engraving machine and take your DIY projects to the next level?

Our final choice

The Gweikecloud Home Laser Cutting and Engraving Machine is a great investment for DIY enthusiasts and small business owners who want to add a personal touch to their creations. With its versatility and multiple connectivity options, it’s definitely worth considering despite the high initial cost. Just make sure you have a dedicated space for it.